Laser Cutting Machine Accessories

Laser Cutting Machine Accessories Specification

- Type

- Laser Cutting Machine Accessories

- Material

- Stainless Steel

- Application

- Laser Cutting Machine

Laser Cutting Machine Accessories Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- Daman and Diu, Gujarat, Madhya Pradesh, Rajasthan

About Laser Cutting Machine Accessories

Laser Cutting Machine Accessories are the simple to use adjuncts, which can be kept in a right position. The accessories are accessible with the extremely accurate process and need less time to work. The accessories can reduce the risk of contaminating material. Also, these can lessen the possibility of material deformation. Their fixture and replacement is quite easy. Other than that, the accessories are suited for the cutting of sheet metal. It is useful in the cutting of wide range of materials such as ceramics, plastic, wood, rubber and others. It has amazingly versatile technology and can find usability in the complex structures.

Technical Specifications:

| Model | STA-Z-001 |

| Outline | 600x100x600 mm |

| Travel | 300mm |

| Weight | 12 Kgs |

Durable Stainless Steel Construction

The accessories are manufactured using premium stainless steel, ensuring exceptional durability and resistance to corrosion even in demanding industrial environments. The polished surface finish provides an attractive appearance and simplifies maintenance, making these fitting choices for professionals seeking longevity and reliability from their equipment.

Precision Engineering for Enhanced Performance

Every accessory is meticulously designed for compatibility with standard laser cutting machines. Precision engineering ensures seamless integration and optimal functioning, contributing to consistent cutting results and increased overall machine efficiency. The components cater to various needs, such as improved beam control and accurate material manipulation.

FAQs of Laser Cutting Machine Accessories:

Q: How do these laser cutting machine accessories improve operational efficiency?

A: By providing precision-engineered parts like nozzles, lens holders, and mirrors, these accessories optimize the laser beams focus and movement, resulting in smoother cuts, reduced downtime, and consistent performance for standard laser cutting machines.Q: What materials are used in the construction of these accessories?

A: These accessories are made from high-quality stainless steel, offering durability and resistance to corrosion, while their polished metallic silver finish ensures easy maintenance and improved longevity.Q: When should I replace or upgrade my laser cutting machine accessories?

A: Regular inspection should be conducted, and accessories should be replaced if there are signs of wear, reduced cutting quality, or after reaching the manufacturers recommended lifespan to maintain high performance and safety.Q: Where can these accessories be used or sourced in India?

A: These laser cutting machine accessories are suitable for a wide range of industrial workplaces and are available through exporters, importers, manufacturers, and suppliers across India.Q: What is the process for installing these laser cutting machine accessories?

A: Installation typically involves following manufacturer instructions for each accessory typesuch as securing nozzles, aligning mirrors, or setting up lens holdersto ensure proper fit and alignment with your laser cutting machine.Q: Can these accessories be customized for different laser cutting applications?

A: Yes, the weight, thickness, and shape of the accessories can be tailored to meet the specific requirements of a given machine or application, ensuring compatibility and optimal operational results.Q: What are the primary benefits of using these stainless steel, corrosion-resistant accessories?

A: The main benefits include improved durability, reduced risk of corrosion, enhanced precision, and higher efficiency, ultimately leading to better cutting quality and extended equipment lifespan.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Laser Machine Accessories Category

Plastic Laser Marking Machine

Price 400000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Laser Engraving Machines

Material : MS

Product Type : Laser Marking Machine

Size : Standard

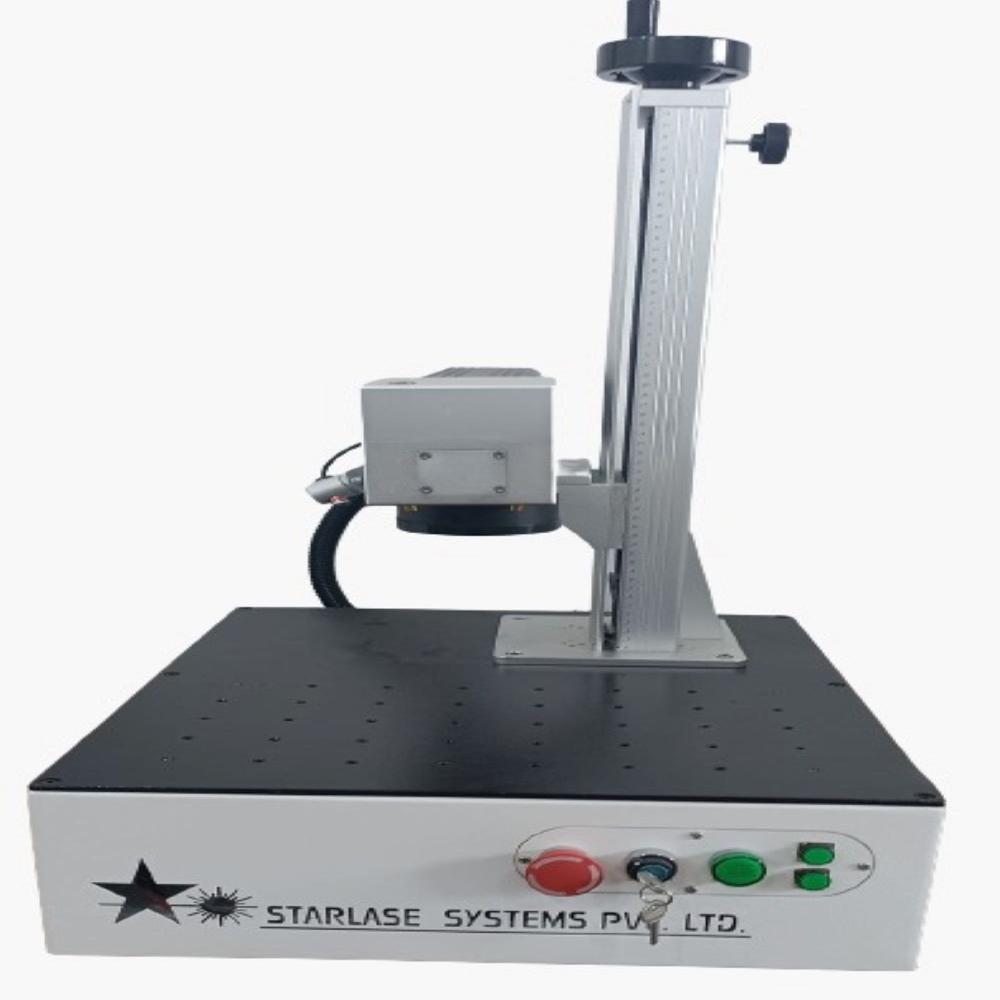

Table Top Fiber Laser Marking Machine

Price 160000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Fiber Laser Marking Machine

Material : MS

Product Type : Fiber Laser Marking Machine

Size : Standard

Laser Marking on gold 20w

Price 200000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Laser Marking

Material : MS

Product Type : Laser Marking

Size : Standard

Laser Cleaning Machine

Price 500000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Laser Machine

Material : MS

Product Type : Laser Machine

Size : Standard

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free