Logo Marking Machine

Logo Marking Machine Specification

- Marking Area

- 110 x 110 mm (Standard), Optional up to 300 x 300 mm

- Marking Speed

- 7000 mm/s

- Condition

- New

- Laser Type

- Fiber Laser

- CNC

- Yes

- Cooling Mode

- Air Cooling

- Control Software

- EZCAD

- Accuracy

- 0.01 mm

- Power

- 20W / 30W / 50W

- Dimensions

- 730 x 430 x 770 mm

- Automation Grade

- Automatic

- Supply Voltage

- AC 220V / 50Hz

- Net Weight

- Approx. 50 kg

- Minimum Character Height

- 0.2 mm

- Interface

- USB

- Usage

- Metal and Non-metal Marking

- Minimum Line Width

- 0.015 mm

- Supported File Formats

- PLT, DXF, BMP, JPG, TIF, etc.

- Focal Distance

- 160 mm (Standard)

- Beam Quality

- M2 < 1.5

- Operating Temperature

- 0 - 40°C

- Focus Mode

- Manual and Auto

Logo Marking Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 1 Months

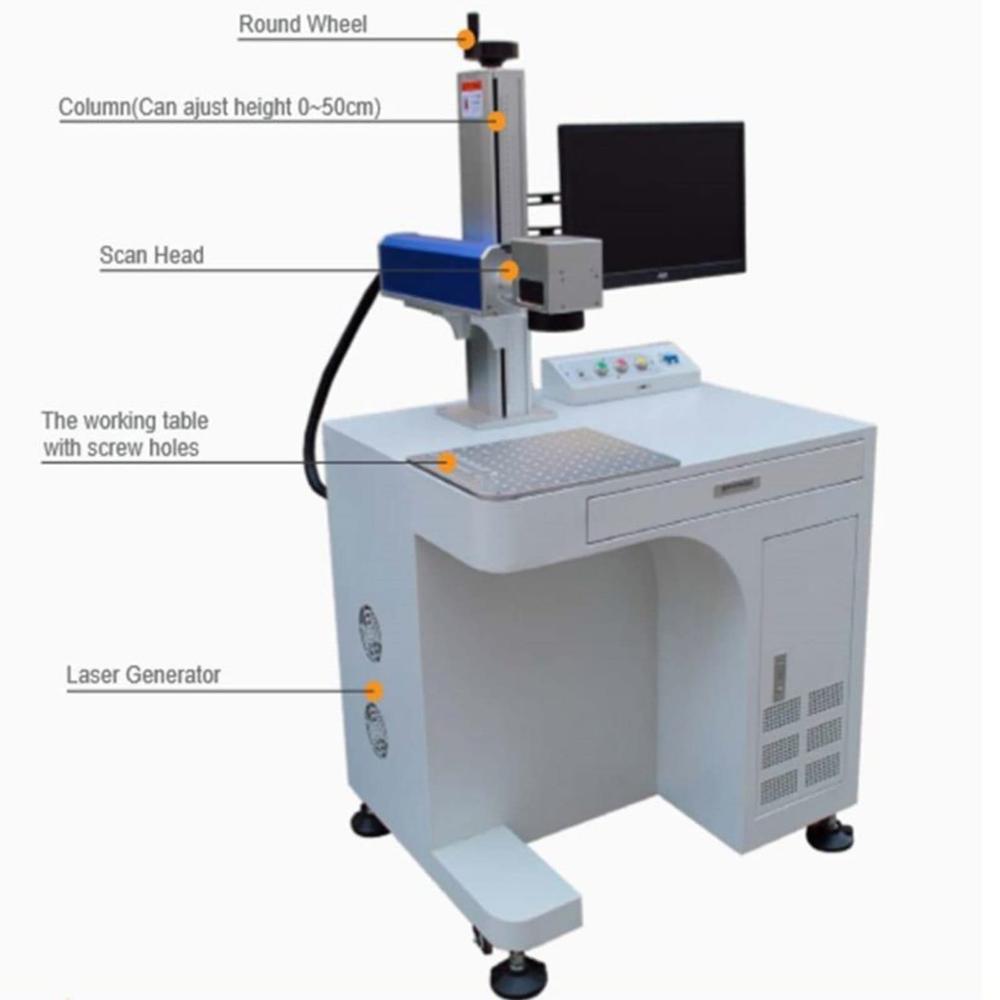

About Logo Marking Machine

Offered Logo Marking Machine, offered by Starlase Systems Private Limited can provide marking on all materials. It can make intricate patterns on metal, plastic, ceramic and glass. The said machine is ideal for marking the logo on different metal surfaces. Logo Marking Machine, supplied, manufactured and exported by us allows for effortless maintenance services. The machines have various significant advantages over the traditional processes. Offered are the innovative forms of marking that get demanded in different sectors.

Logo Marking Machine Technical Details:

Fiber Source :: SUPER / MAX /RAYCUS LASER SOURCE/JPT/IPG Life time 100000 hrs

Scanner: Digital Scanner

Interface card: Star Laser Technologysoftware

Interface PC: PC

Moving Parts: HIWIN / Tamagawa ( japan)/Oriental(USA)

Advanced Precision Marking Technology

Utilizing a fiber laser with a superior beam quality (M2 < 1.5), this machine delivers fine markings with a minimum line width of just 0.015 mm and a minimal character height of 0.2 mm. The system integrates CNC functionality, offering highly accurate engravings ideal for branding, serialization, and customizing both metal and non-metal products.

Versatile Functionality and Automation

With both manual and auto focus options, this automatic logo marking machine adapts easily to varying product surfaces and shapes. Its universal USB interface and compatibility with popular graphic formats allow effortless integration into production lines or stand-alone workshops, increasing productivity and workflow efficiency.

Robust Build and User-Friendly Operation

Constructed to withstand demanding industrial environments, the machine features air cooling for stable operation between 0 - 40C, a compact 730 x 430 x 770 mm footprint, and a net weight of approximately 50 kg. EZCAD software provides intuitive operation, enabling users to manage projects seamlessly while ensuring safety and consistency in output.

FAQs of Logo Marking Machine:

Q: How does the Logo Marking Machine operate on different materials?

A: The machine uses fiber laser technology, allowing it to mark a wide range of materials, including both metals and non-metals. Users can adjust focus manually or automatically to achieve optimal results on various surfaces, ensuring precise and clear markings each time.Q: What file formats are compatible with this marking machine?

A: This machine supports a diverse set of file formats such as PLT, DXF, BMP, JPG, TIF, and more. This compatibility ensures seamless workflow integration with most design and CAD software, making it versatile for different marking requirements.Q: When should I use manual versus auto focus during marking?

A: Auto focus is best used for standard materials and consistent product heights, increasing efficiency for repetitive jobs. Manual focus is recommended when working with products of varying thickness or unique contouring to ensure accurate focal distance and optimal marking quality.Q: Where can this laser marking machine be effectively used?

A: This machine is ideal for use in industrial settings, manufacturing lines, workshops, and small businesses involved in product branding, serialization, component identification, or decorative engraving. Its robust build makes it suitable for demanding environments.Q: What steps are involved in preparing the machine for marking?

A: First, connect the machine to a power source and ensure proper air cooling. Load your desired graphic file via USB. Set up the marking parameters in EZCAD, adjust the focus (manually or automatically), and place your material within the marking area before initiating the marking process.Q: What are the benefits of using this automatic marking machine for exporters and manufacturers?

A: Exporters and manufacturers benefit from fast, accurate, and repeatable markings with minimal maintenance. The machines automation, precision, and compatibility with diverse materials enhance productivity, reduce error rates, and deliver high-quality marks suitable for international standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Laser Marking Machines Category

Metal Laser Marking Machine

Price 300000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Cooling Mode : Air Cooling

Laser Type : Fiber Laser

Jewellery Laser Marking Machine

Price 300000.0 INR / Unit

Minimum Order Quantity : 1 Piece

Condition : New

Cooling Mode : Air Cooling

Laser Type : Fiber Laser

Label Marking Machine

Price Range 200000.00 - 900000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Cooling Mode : Other, Air Cooled

Laser Type : Fiber Laser

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS