Mold Welding Machine

Price 1000000 INR/ Box

Mold Welding Machine Specification

- Weight

- 15 kg

- Cooling Method

- Air Cooling

- Efficiency

- 85%

- Frequency

- 50-60 Hz

- Type

- Mold Welding Machine

- Output Current

- 2-200A

- Motor Type

- Stepper Motor

- Pulse Frequency

- 1-200 Hz

- Welding Area

- 3-10 mm

- Insulation Grade

- F

- Voltage

- 220V

- Input Current

- 10A

- Rod Diameter

- 0.2-2.0 mm

- Dimension (L*W*H)

- 430 x 205 x 275 mm

- Function

- Micro welding of molds and metals

- Usage

- For precision mold welding and repair

- Arc Current

- 2-200A

- Condition

- New

- Power

- 100W

- Material

- Stainless Steel

- Packaging Details

- Export standard wooden case

- Welding Mode

- Pulse/Continuous

- Welding Wire Material Compatibility

- Steel, Copper, Aluminum, Titanium

- Display

- Digital

- Control Panel

- Touch/Keypad Interface

- Ambient Temperature Range

- -10°C to 40°C

- Duty Cycle

- 60% at max output

- Storage Temperature Range

- -20°C to 60°C

- Safety Feature

- Overload and Temperature Protection

Mold Welding Machine Trade Information

- Minimum Order Quantity

- 1unit Box

- Supply Ability

- 1 Box Per Week

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About Mold Welding Machine

Available in two models, this Mold Welding Machine uses YAG laser source. Its wavelength is 106 NM and its power output is maximum 400W. Its pulse energy ranges between 100 to 150J and pulse width range is 1-20 MS. Frequency of this Mold Welding Machine ranges between 1 HZ to 100 Hz. Application of water cooling technology, 15 KW peak power, 600 kg weight and accessibility in DSP 4 axis bases electric or manual design choice are the main features of this machine.

|

TECHNICAL DETAILS

|

| MODEL | WM400 | WC400 |

| LASER | YAG | YAG |

| WAVELENGTH | 1064NM | 1064NM |

| MAX.POWER OUTPUT | 400W | 400W |

| MAX PULSE ENERGY | 100-150J | 100-150J |

| PULSE WIDTH | 1-20MS | 1-20MS |

| FREQUENCY | 1-100HZ | 1-100HZ |

| COOLING SYSTEM | WATER | WATER |

| PEAK POWER | 15KW | 15KW |

| POWER REQUIREMENT | 380 AC / 50 Hz / 40 A | 380 AC / 50 Hz / 40 A |

| CNC / AXIS | DSP 4 AXIS ELECTRIC / MANUAL | DSP 4 AXIS ELECTRIC / MANUAL |

| WEIGHT | 600KG | 600KG |

|

LASER WELDING

|

Precision Welding Capabilities

Engineered for accuracy, this mold welding machine allows users to perform micro welding tasks on areas ranging from 3 to 10 mm. Its compatibility with multiple wire materials, including steel, copper, aluminum, and titanium, ensures versatility across different repair and fabrication projects. The adjustable arc current (2-200A) and pulse frequency (1-200 Hz) make it perfect for precise mold restoration.

User-Friendly Controls

Equipped with a digital display and a choice between touch or keypad interfaces, users enjoy intuitive operation with accurate parameter adjustments. The control panel simplifies the welding setup process, allowing professionals of varying experience levels to achieve optimal results with ease.

Robust Safety Features

With advanced overload and temperature protection mechanisms, this welding machine prioritizes operator safety during use. Designed to function reliably in ambient temperatures from -10C to 40C, and able to withstand storage conditions between -20C to 60C, its construction meets export standards for quality and durability.

FAQs of Mold Welding Machine:

Q: How does the Mold Welding Machine ensure safety during operation?

A: The machine incorporates overload and temperature protection systems to safeguard both the operator and the equipment. These features automatically shut down or regulate the system if unsafe conditions are detected, minimizing risk during usage.Q: What welding wire materials are compatible with this machine?

A: This welding machine supports a range of wire materials, including steel, copper, aluminum, and titanium, making it suitable for diverse mold repair tasks and metalworking applications.Q: When is it appropriate to use the pulse or continuous welding modes?

A: Pulse mode is ideal for delicate micro welding and precision repairs, while continuous mode is best for extended welds or larger repair areas. The operator can switch between modes based on the specific requirements of the job.Q: Where is this welding machine typically used?

A: The Mold Welding Machine is primarily utilized in industrial settings for mold repair and precision welding. It is favored by exporters, importers, manufacturers, and suppliers across India for workshop and maintenance operations.Q: What is the process for setting up the welding machine for operation?

A: To set up, place the unit on a stable surface, connect it to a 220V power source, select the desired welding wire and rod diameter (0.2-2.0 mm), adjust the arc current and mode on the touch/keypad interface, and follow the digital display prompts for parameter confirmation.Q: How does this machine benefit mold repair professionals?

A: Its micro welding capabilities and compatibility with various metals allow professionals to achieve high-precision welds, reducing downtime for mold maintenance and improving overall productivity. The efficient air cooling system and 60% duty cycle support continuous operation for demanding tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Laser Welding Machines Category

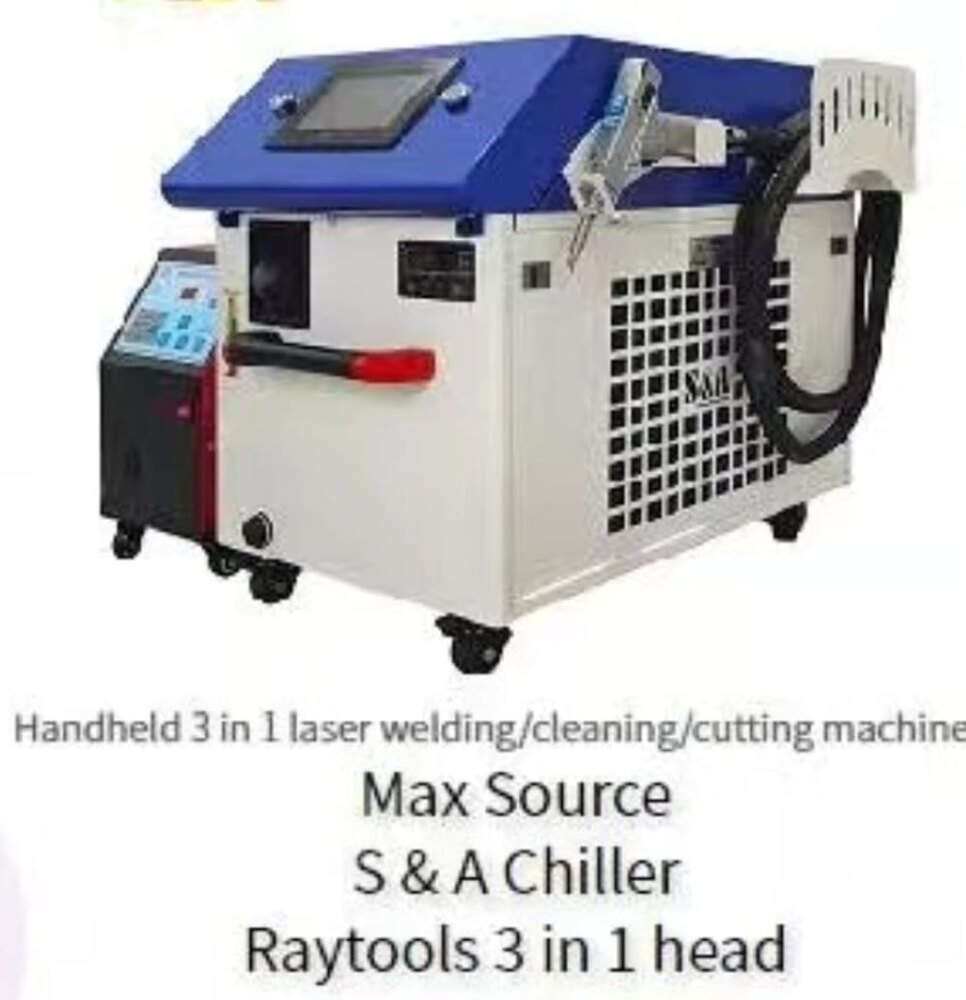

Hand Held Welding Maching

Price 650000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Type : laser welding machine

Voltage : 250 Volt (v)

Laser Welding Machine

Price Range 250000.00 - 750000.00 INR / Unit

Minimum Order Quantity : 1 Piece

Condition : New

Type : CNC Type

Voltage : 220 Volt (v)

Imitation Jewellery Laser Soldering Machine

Price 350000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Type : Soldering Machine

Voltage : 110215 Volt (v)

Hand Held Welding Machine

Price 500000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Type : Hand Held Welding Machine

Voltage : 110215 Volt (v)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free